Um tipo de metal, como o aço, é usado para fazer tubos longos e finos chamados tubos de aço com rosca. A parte externa desses tubos possui pequenas ranhuras, conhecidas como rosca, que se enrolam ao redor do tubo. Essas rosca são muito úteis pois permitem que o tubo seja conectado facilmente a outros. Ideal para Muitas Situações Os tubos de aço com rosca podem ter várias utilidades e possuem várias vantagens.

Um grande bônus dos tubos de aço com rosca é o quão fortes eles são. Este é o tipo de força sobre o qual as pessoas falam, capacidade de suportar uma alta pressão/peso sem sequer se curvar ou quebrar. Ao considerar levantar objetos pesados, você precisaria de alguma força em uma ferramenta. Além disso, os tubos de aço com rosca são projetados para resistir à corrosão. A ferrugem é o resultado natural do que acontece quando o metal oxida em um ambiente úmido ou cheio de ar devido à corrosão. Os tubos de aço com rosca muitas vezes são a opção perfeita devido à resistência à corrosão que oferecem, o que os torna adequados para uso em diversas aplicações e configurações.

Por isso, os tubos de aço roscados são ideais para trabalhos de alta pressão. Isso significa que, se você tiver gases e líquidos para transportar em altas pressões, esses tubos podem realizar um ótimo trabalho movendo-os com segurança. É bem parecido com quando um balão muito resistente é continuamente inflado e nunca estoura. Eles são muito confiáveis, pois não se deformam ou se partem sob altas pressões.

Variedade de Locais Diferentes Onde Estes São Tubos Utilizados. Eles ocorrem de várias maneiras, como mencionado abaixo em relação a sistemas de encanamento e aquecimento. Esses sistemas dependem de tubos de aço com rosca para transportar água e outros fluídos entre edifícios, tudo isso contribui para o funcionamento suave. Além disso, eles são até utilizados em oleodutos e gasodutos. A fachada também é significativa devido aos dutos que devem abrigar, pois esses tubos processam forças de alta pressão e não se corroem. Tubos de aço com rosca contribuem amplamente na área da construção civil também. Eles sustentam edifícios e criam a estrutura forte que nos mantém em pé.

Levando em consideração que os tubos de aço com rosca podem durar longos períodos de tempo devido à sua força, qualquer contratante de construção pode optar por essa solução. Eles permanecerão em boas condições ao longo do tempo e especialmente sob alta pressão. Então, a melhor parte é que eles não vão se danificar facilmente ou em um momento ruim. É como um amigo confiável que nunca te deixa sozinho na hora da adversidade.

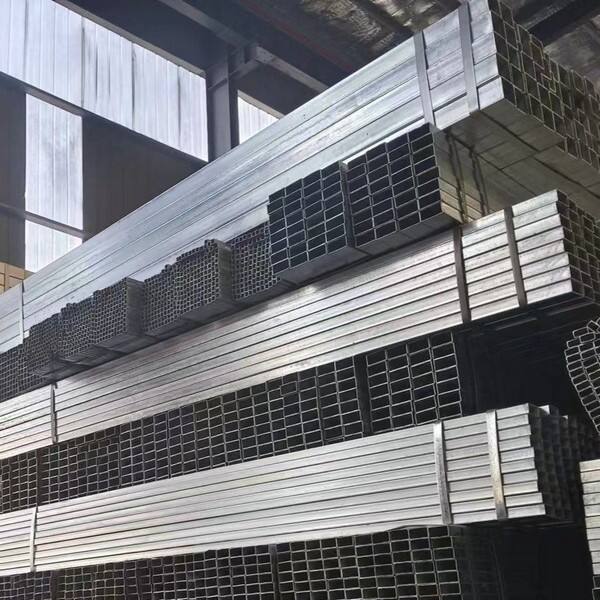

Existem muitos tipos de materiais para tubos de aço, como o aço carbono comum e os aços carbono estruturais de alta qualidade. Por exemplo: extremidade roscada / soquete conforme API 5L GR.B MWT PIPE de 1/2 "até vinte" (21 três mil metros lineares); (Nota: seleção de tipo não testado para sua especificação do P.O. obter +86-318-226430 Data =) já que a maioria dos produtos é usada em poços de gás; é necessário que você nos informe qual tipo é mais adequado para o propósito, para que possamos lhe fornecer um orçamento de acordo. Por exemplo, alguns foram feitos de um tipo resistente de aço chamado aço carbono, que é capaz de suportar muito mais cargas de pressão. Outros são feitos de aço inoxidável, bom para evitar ferrugem em condições úmidas ou molhadas.

Os tamanhos de tubos de aço com rosca podem variar muito. No diâmetro, alguns tubos são muito pequenos (alguns polegadas de largura), enquanto outros podem ser maiores, medindo vários pés de largura. O quão grande, ou que tamanho de tubo de PVC você precisa dependerá do tipo que está tentando usá-lo e, às vezes, de quanto pressão precisa suportar. Você precisa ajustar o tamanho para que funcione corretamente!