Top Reasons for 10 Steel Pipe in Construction Projects Steel pipes are a staple in the construction industry, especially in tasks that require heavy lifting as they provide excellent strength, rigidity and flexibility. They are commonly used for liquids, gases and various substance. Out of the many steel pipes available, 10 steel pipe is one of the best for a wide range of applicability: Work reasons for 10 Steel pipes The best choice for excruciating construction tasks is the rigid structure of 10 steel pipes. They are used in the industrial setting critical tasks. First, 10 steel pipe, called schedule 10 pipe is first for hard jobs because of its superior strength. This tube has two distinct methods of production, of which the first is seamless, other is welded. Under the utmost heat, two steel pieces are pressed together to meld with each other and create a seam in the weld variation, while the seamless is produced without any weld seams. It results in greater strength of the seamless version, while welding under extreme pressure may lead to a weakened joint where the heat distributing was less than average. Schedule 10 steel pipe is often made from the weld method due to its lower cost. Schedule 10 steel pipe has many advantages over other versions of the pipe. Compared to the higher-end schedule 40 and schedule 80 steel pipe, it is less expensive. It also has much better resistance to corrosion and is designed for low-pressure use compared to many of the other steel pipes in construction. All that being said, the tube is not the most durable. Although stronger than regular tubing, it is less sturdy than other high-end versions. On tasks that require a little bit more strength to the pipe and a little bit thicker material, you need to look elsewhere.

Choosing the Right 10 Steel Pipe for Your Industrial Project The first aspect to consider when making your choice is purchasing a 10 steel pipe appropriate in length and diameter. Furthermore, based on what you are going to use the pipe for, you will purchase a fitting one to transport various liquids or gases. Lastly, you will also consider the environment where the pipe is going to be situated. If it is directly exposed to the sun or rain, it must be a pipe fit for such circumstances. Installing and Maintaining 10 Steel Pipe with Care and Professionalism Installation and maintenance that will be done in the right manner is vital for the performance and longevity of 10 steel pipe. If you are not sure how to go about it, leave it to the professionals. Regular checks must be done for signs of damage because, just as any other 10 products, this one needs to be well maintained, cleaned, and lubricated to avoid corrosion for optimal active life. There are a Few Things to Always Remember When Purchasing the 10 Steel Pipe When working with it, you must always utilize the specific tools for this product. Additionally, you must always wear protective clothing when working on the pipe. Moreover, you must always follow all the regulations as described in the guideline on your industry’s work.

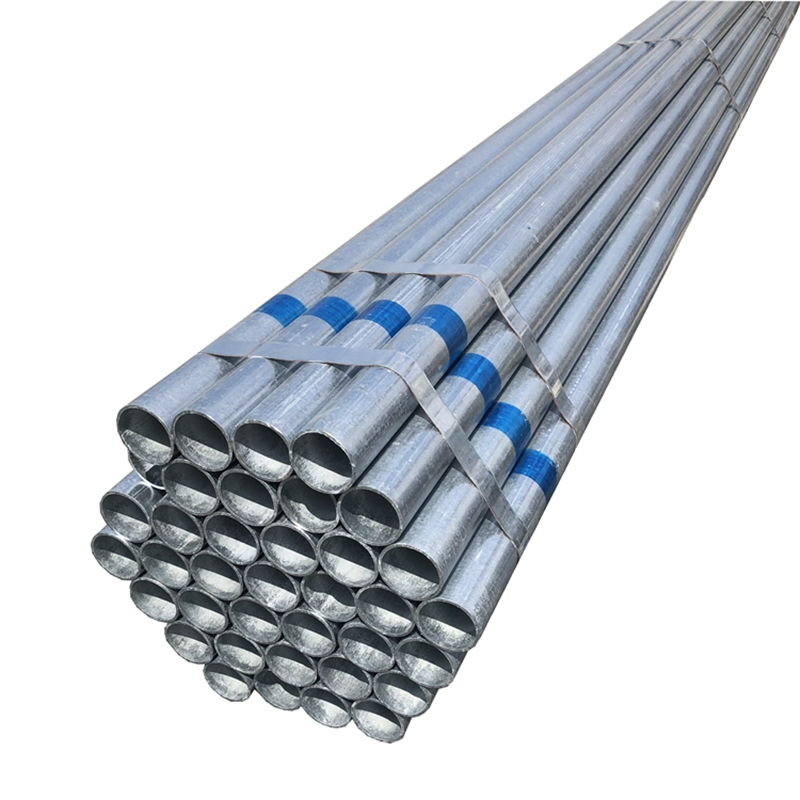

Steel pipes are essential to numerous industries, from construction to manufacturing. There are many different types of steel pipes available, but , we will focus on 10 steel pipes. What are they, and what sets them apart?

When we say 10 steel pipe, we are referring to a particular type of steel pipe. This type of pipe has a diameter of 10 inches. It is a large, heavy-duty pipe that is used in a variety of applications. What makes 10 steel pipe unique is its size and strength. It is designed to withstand high pressure and heavy loads, making it ideal for use in industries such as oil and gas, infrastructure, and construction.

As mentioned, 10 steel pipe is most commonly used in industries such as oil and gas, infrastructure, and construction. In the oil and gas industry, it is used for transporting oil and gas from drilling sites to refineries and distribution centers. In infrastructure, it is used for water and sewage systems, as well as for bridges and other large structures. In construction, it can be used for building supports, foundations, and other structures that require a strong and durable material.

One of the primary advantages of 10 steel pipe is its strength and durability. It can withstand high pressure and heavy loads, making it ideal for use in heavy-duty applications. Additionally, it is resistant to corrosion, which means it will last longer than other materials. It is also easy to install, making it a popular choice for contractors and builders. Finally, 10 steel pipe is environmentally friendly, as it is 100% recyclable, which reduces waste.

All of our products are able to provide BV, ISO, SGS, CE and other certificates. We oversee every aspect of production quality, ensure that it is strictly controlled and provide testing results, however, we also permit testing by third parties. The 10 steel pipe is to offer customers superior quality products made of steel.

We have established a relationship with more than 10 steel pipe steel producers at home and abroad, can provide carbon steel, alloy steel, stainless steel plate, tubes, coil, all types of profiles as well as hardware accessories, committed to providing customers with the most appropriate solutions to meet individual customer specifications.

We have plenty of expertise in transport 10 steel pipe borders offering products and services to more than 80 countries. Our logistics team is reliable, and we offer sea, air and land transportation. Our goal is to ensure the most efficient, safest delivery.

We offer 10 steel pipe with a 24 hours online after-sales service If there are any issues following the arrival of the products including packaging or how the goods appear it will be our first time to solve, should the issue not be resolved remotely, we'll send the relevant technical staff to help solve the problem.